PRODUCTS

- 首頁

- 經營品牌

- Hologenix Inc.

- 缺陷檢查設備

- Automated Microscope for CD, Overlay, and Defect Detection System

Automated Microscope for CD, Overlay, and Defect Detection System

Hologenix

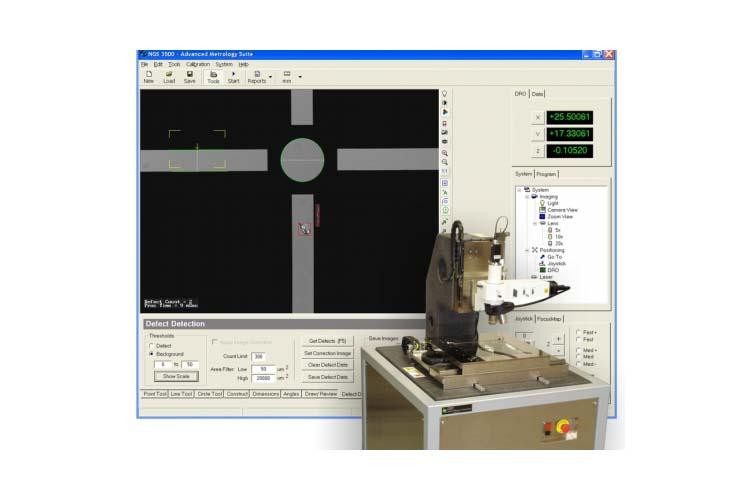

NGS 3500L – Advanced Metrology System

APPLICATIONS

。Wafer level defect detection & measurement

。Precision MEMS and HD component inspection

。Advanced microelectronics package inspection

POWERFUL

。Designed for automatic/ semi-automatic operation

。Extensive Defect Detection features & capability

。Integrated Dimensional Metrology features

PRECISE

。Sub-micron precision optical measurements

。High accuracy staging with 0.02 um linear encoder resolution

FAST

。50-100 defects/ measurements per second typical per field of view

。200mm/ second part staging speed

USER FRIENDLY

。Very easy to use, program and set up

。Highly visual data with rich color graphics & Video

FLEXIBLE

。Nomarski Microscope and other advanced options

。Optional Wafer and other part types handling

。Customizable for application specific solutions

NGS 3500L – Advanced Metrology System

。 200mm (optional 300mm) wafer/ part size capacity

。 Maximum stage Load capacity: 50 lb

。 250mm/ second maximum staging speed

。 Granite base and Z-column, stainless steel finish

。 Class 100 (10 optional) clean room compatible

。 Closed loop linear stages, with position feedback from 0.05 um resolution linear glass encoders

。 Non-linear 2D accuracy error correction

。 Accuracy U2 (XY): 1.5+0.6L/100 um, U1 (Z): 1.5+3L/100 um. Where L is length in mm

。 Computer: Windows High Performance PC

。 Platform:High Performance 3000L

。 Software: NGS 3500L Advanced Metrology Suite

。 Optical System: Flat Field objectives, with optional motorized 5 position turret

。 Camera: High resolution CCD array 60+db S/N ratio

。 Image Processing 256 grayscale with 1:5-1:50 subpixel ratio. Optional 5 MP Color or 5MP Grayscale

。 Video and optional Laser Auto focus

。 Illumination: software controlled Coaxial & backlight

。 Environmental: 17-23 deg C, 20-80% Humidity

。 Electrical 120/240 VAC, 15A single phase

。 Footprint: WxD: 32x36 inch. Height: 67 inches

。 Weight: 1500 lb crated

NGS 3500L – Advanced Metrology System

。 Automatic defect detection and classification

。 Graphical Defect maps, Image Archival, offline review of defects, and reprocessing of archived images

。 Flexible part scanning for operator convenience and throughput optimization

。 High Precision vision based part alignment

。 Dimensional Metrology Tools:

Video Tools: Point, Line, Circle, Arc edge detectors with built in best fit and defect removal

Constructions: Extensive geometric constructions, with distance and angle measurements (e.g. line to line, etc.)

Origin & Skew: Unlimited reference frames

Tolerancing: Dimensional, Angular, Geometric True Position (MMC, LMC, RFS)

Units: Metric & inches

Coordinates: Cartesian & Polar

Step & Repeat: Repeat Loops for repeating features and multiple parts

Reports: Data on screen, text file, or exports to Excel

SPC: Average, SD, Range, Min, Max, Cp, Cpk

Graphics & CAD: Drawing import/ Export

Other: Auto Focus, Auto Lighting & Outlier Removal

Automatic Defect Detection & Classification

Automated Die Inspection

Precision Dimensional Metrology

Critical Dimension (CD) and Overlay Metrology Automatic and Manual Operation

- VCSEL CD Measurement

- Surface & Edge Defect Detection

- Texture Defect Detection (e.g. stains, etc.)

- Missing or Deformed Object Detection

- Extensive Defect Review Capability

- Graphic Maps & Image Archival

- CAD file import