PRODUCTS

- 首頁

- 經營品牌

- Hologenix Inc.

- 缺陷檢查設備

- Defect Detection on Ultra-Flat Wafers (Magic Mirror™)

Defect Detection on Ultra-Flat Wafers (Magic Mirror™)

Hologenix

The Magic Mirror™ is useful for detecting problems with many types of wafer processes:

• Polishing

• Epitaxy

• Oxidation, Diffusion, CVD

• Post Implant Annealing, RTP

• CMP

• SOI

New Capabilities

• High Resolution Camera and Optical Components – 5 MegaPixel Camera

• IR (Infrared) Camera and Optics

• Long Focal Length Version – Greater Detection Capability for Shallow Defects

• Computer Controlled Optical Settings

• Latest Automation Capabilities – Edge handling, Wafer Sorting

Optical Technique

• Halogen Lamp with Band-Pass Filter

• Series of Lenses Create Broad Beam Collimated Light Column

• Parallel Rays of Light Reflect Perpendicular to the Polished Surface – Min. 3% reflectivity required

• Reflected Rays Projected onto De-focused CCD Detector.

Software and Computer Control of Optics

Optics are controlled via a Software Interface:

• Brightness

• Sensitivity

Settings can be stored in a recipe and easily recalled

No operator involvement needed.

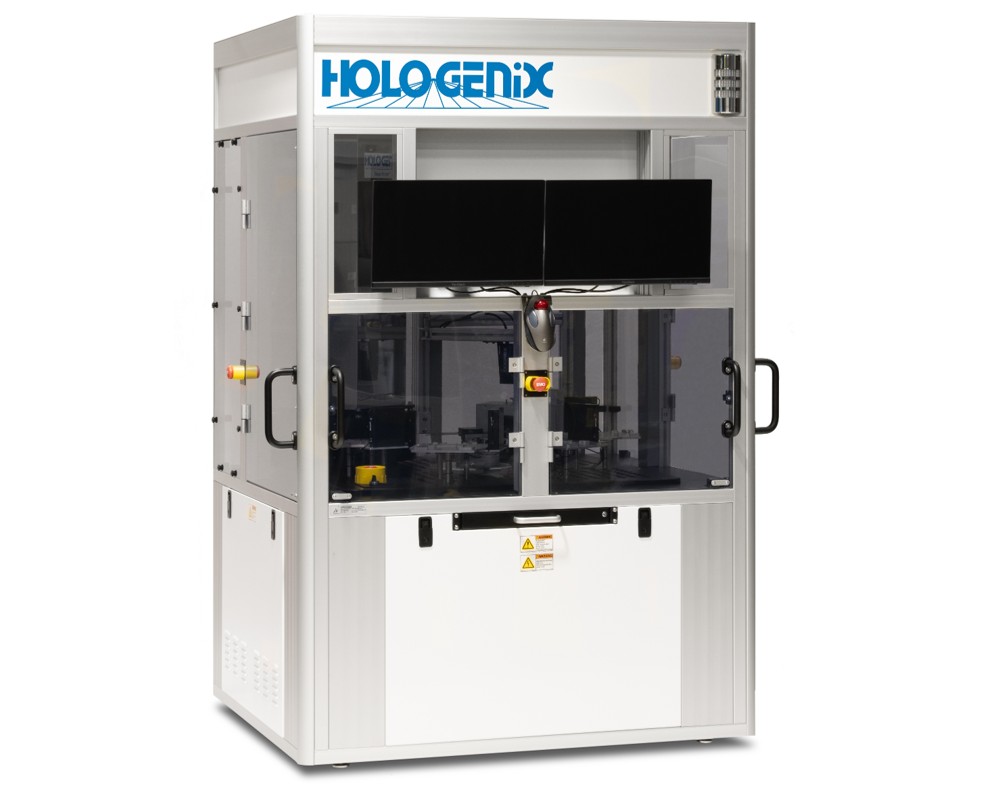

Hologenix YIS-MM-2N Magic Mirror™

2, 3 or 4 Cassette Wafer Surface Inspection Systems

• Automatic Defect Detection with Hologenix ADDS Image Processing Software

• Detection Sensitivity better than 0.05 Micron Depth with <1M-100M Radius of Curvature using the Proprietary Magic Mirror™ Method

• Defect Size Range: 0.4 μm height difference over a 10 mm lateral distance to 0.05 μm over a 0.5 mm lateral distance

• Adjustable Defect Detection and Classification Recipes

• Non-Contact Notch, Flat-Finding and Centering Technology

• 150-200 mm Wafer Inspection

• Throughput: Approx. 150 Wafers per Hour

• 2, 3 or 4 cassettes or SMIF pods. The -2N model #is for 2 open cassettes

• Class 1 Clean Room Compatible

• Windows 10 Environment

• Standalone Sorter Capability with optional OCR

300mm Magic Mirror™ YIS-300SP-2

Automated Defect Detection System

• Detection Sensitivity better than 0.05 Microns Depth

• 13 or 25 Wafer Capacity FOUP or Open Cassette

• Class 0.1 Mini-Environment

• 200-300 mm Wafer Sizes

• Edge Grip Wafer Handling

• Non-contact Notch Finder & Aligner

• SECS II - GEM

• Optional OCR

• Windows 10 Based Defect Detection Software - ADDS

200mm or 300m Magic Mirror™ YIS-200SP or YIS-300SP

Defect Detection System – Manual System

• Detection Sensitivity better than 0.05 Micron Depth

• Full View and 3.5X Zoom

• 200SP – Up to 200 mm Wafer Sizes

• 300SP – Up to 300mm Wafer Sizes

• Computer Controlled Sensitivity

• Computer Controlled Intensity

• Manual Loading

• Rotating Wafer Chuck

• Broad Beam Illumination with Narrow Band-Pass Filtered White Lamp

• Defect Detection and Image Enhancement Software